Keywords:Dust removal seriesPP waste gas treatment towerActivated carbon processorUV photolysis deodorization equipmentElectrostatic oil fume purifier seriesVentilation and cooling series

Keywords:Dust removal seriesPP waste gas treatment towerActivated carbon processorUV photolysis deodorization equipmentElectrostatic oil fume purifier seriesVentilation and cooling series

Service hotline

Service hotlineWorking principle of acid mist purification tower:

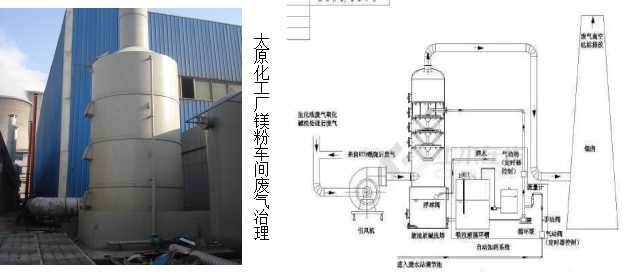

The acid-base gas purification tower belongs to a two-phase reverse flow packed absorption tower. The waste gas enters the purification tower in a tangential direction from the inlet below the waste gas treatment tower. Under the power of the ventilation fan, it quickly fills the intake section space and then uniformly rises to the first stage packing absorption section through the uniform flow section. On the surface of the filler, acidic (or alkaline) substances in the gas phase react chemically with alkaline (or acidic) substances in the liquid phase, producing substances (mostly soluble acids (alkalis)) that flow into the lower storage tank with the absorption liquid. The partially absorbed acidic (or alkaline) gas continues to rise and enter the first stage spray section. In the spray section, the absorbing liquid is sprayed out at high speed from the uniformly distributed nozzle, forming countless small mist droplets that mix and contact with the gas thoroughly, continuing to undergo chemical reactions. Then, the acidic (alkaline) gas rises to the second stage packing section and spray section for a similar absorption process as the first stage.

The density of the second and first stage nozzles is different, the spraying pressure is different, and the concentration range of absorbing acidic (alkaline) gases is also different. The process of contact between the spray section and the packing section is also a process of heat and mass transfer. Ensure the adequacy and stability of this process by controlling the flow rate and retention time of the empty tower. The upper part of the exhaust gas treatment tower is the defogging section, where the absorption liquid droplets trapped in the gas are removed. After treatment, clean air is discharged into the atmosphere through the exhaust pipe at the upper end of the exhaust gas purification tower.

Performance characteristics of acid-base gas purification tower:

1. Waste gas treatment equipment has a wide range of applications: organic waste gas, sulfuric acid, nitric acid, hydrochloric acid, hydrofluoric acid and other tail gases emitted from industrial sectors such as chemical, light industry, printing and dyeing, medicine, steel, machinery, electronics, instrumentation, electroplating, etc., as well as acidic gases such as sulfur oxides (SOx), nitrogen oxides (NOx), carbon oxides (CO, CO2), cyanide (HCN), etc., can be purified using Guanglv industrial waste gas purification equipment, and satisfactory results can be achieved.

2. High exhaust gas purification efficiency: The acid (alkali) mist exhaust gas purification tower adopts a two-stage reverse spray, with a large specific surface area of the packing. The gas ratio determined by experimental research ensures stable performance, and the purification efficiency for various concentrations of acidic (or alkaline) exhaust gas can reach 85%~95%.

3. Low resistance of waste gas treatment equipment: On the basis of ensuring sufficient gas-liquid contact area, Anjule Industrial Waste Gas Purification Tower selects packing varieties and structural forms with excellent aerodynamic characteristics, so that the equipment resistance does not exceed 40 millimeters of water column under rated air volume. It is one of the low resistance packing absorption towers in China. This is extremely beneficial for the use of corrosion-resistant low-pressure ventilation fans.

4. The waste gas treatment equipment occupies a small area: The Anjule industrial waste gas purification treatment tower is made of PP, FRP and other materials. The tower body, absorption liquid tank, circulation pump, and absorption liquid pipeline system are combined to form a complete set of industrial waste gas treatment equipment, with a compact structure that is easy to install and operate on site